OUR SOLUTIONS

Compatible Industries

This machine is perfectly matched to the following industry applications

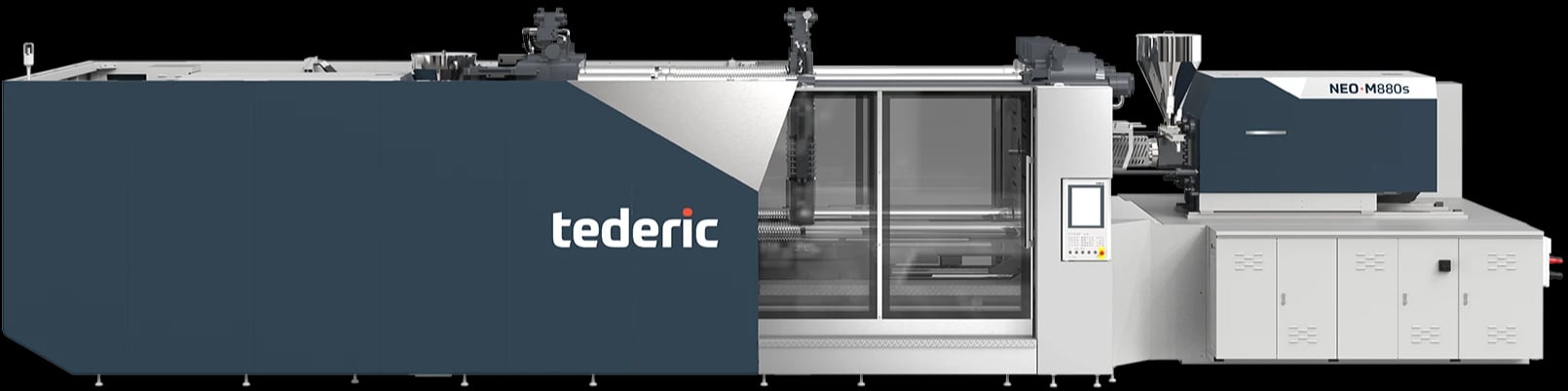

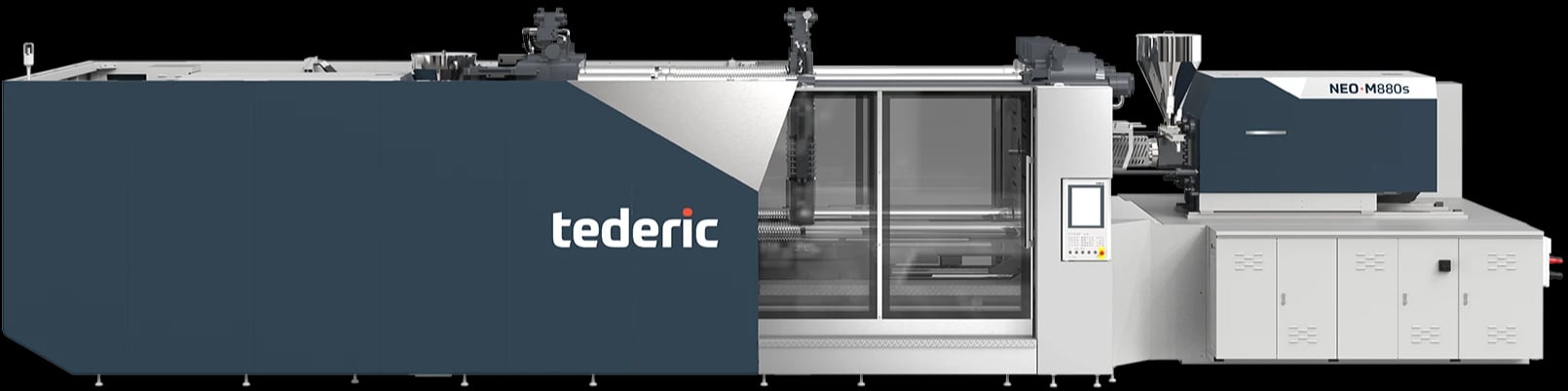

NEO·Ms Injection Molding Machine with Opposite Units and Horizontal Rotary Table

NEO•Ms

The horizontal NEO Ms injection molding machine with rotary table, winner of the Industrial Innovation Award, has a compact mechanical design, excellent performance, and enables easy multi-functional implementation.

Specifications

Clamping Force:1120t-3520t

Clamping Structure:Two-Platen System

Power System:Hydraulic and Hybrid Hydraulic-Electric

Control System:Advanced multi-unit control system

Injection Speed:High-speed multi-component injection

Key Features

- Combination of two-platen clamping system and opposite injection unit ensures molding of complex two-color products in a smaller footprint.

- Ensures weight accuracy ≤0.3%, flexible customization services, professional solutions tailored to customer product characteristics.

- Horizontal rotary table design for efficient multi-color molding.

- Opposite injection units enable complex product structures.

- Space-saving design suitable for production facilities.

- Flexible configuration for various multi-component applications.

- Precise color transition control for quality products.

- Rapid mold changeover for production versatility.

- Synchronized injection control for uniform quality.

- Robust construction for continuous production.

Ask about this machine

We'll contact you about NEO•Ms

Select your voivodeship to see contact details for your regional sales representative.